Features

Rated working pressure: 21 MPa

Heat resistance: 120℃

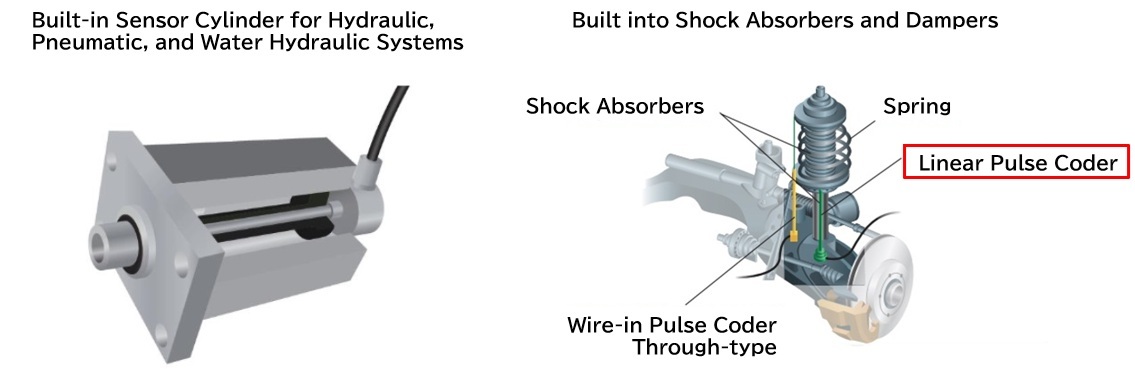

Can be built into hydraulic (oil) pressure / pneumatic / aqua (water pressure) cylinders

Custom orders starting from one unit available.

.png)

Model

| LP | 40 | – | 050 | – | LFH | – | 1 |

|---|---|---|---|---|---|---|---|

| ① | ② | ③ | ④ | ⑤ |

| ① | Model classification | LP | : | Linear Pulse Coder |

| ② | Sensor diameter (mm) | 40 | : | φ4.0 |

| ③ | Measuring range (mm) | 050 | : | 50 |

| ④ | Shape of mounting part | LFH | : | Flange |

| R8H | : | M8 screw | ||

| ⑤ | Amplifier | 1 | : | CV05 |

| 2 | : | CVS5 | 3 | : | CV06A | 4 | : | CV06D |

Specification

| Model | LP40-LFH/R8H | |

|---|---|---|

| Sensor diameter(mm) | φ4 | |

| Target | Material | Brass pipe(C2700) |

| Outer diameter(mm) | φ6(-0.01/-0.05) | |

| Inner diameter(mm) | φ5(±0.03) | |

| Linearity (mm) | ±2%/FS or less | |

| Temperature characteristics | ±2.6%/FS or less (0 to 80℃ @ center of measurement range) | |

| Operating temperature range(℃) | -10~80 | |

| Lead-out cable | Length(m) | 2 |

| Outer diameter(mm) | φ4.8 cross-linked PE coated shielded cable | |

| Protective structure | equivalent to IP67 | |

| Pressure resistance | 21 MPa (Pressure test: 35 MPa [10min]) | |

| Magnetic field resistance | 0.2T (Tesla) | |

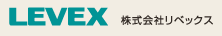

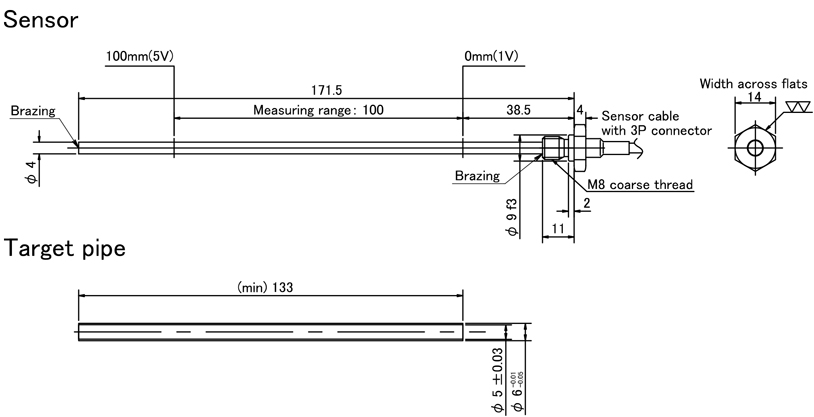

Outline drawing

LFH flange type (Cable pull-out direction : Vertical)

| (mm) | |||||

| Model | A | B | FS | L | Q |

|---|---|---|---|---|---|

| LP40-015-LFH | 20 | 16 | 15 | 51 | 45 |

| LP40-030-LFH | 30 | 66 | 60 | ||

| LP40-050-LFH | 50 | 86 | 80 | ||

| LP40-075-LFH | 75 | 111 | 105 | ||

| LP40-100-LFH | 100 | 136 | 130 | ||

| LP40-125-LFH | 125 | 161 | 155 | ||

| LP40-150-LFH | 40 | 30 | 150 | 220 | 200 |

| LP40-175-LFH | 60 | 175 | 265 | 245 | |

| LP40-200-LFH | 200 | 290 | 270 | ||

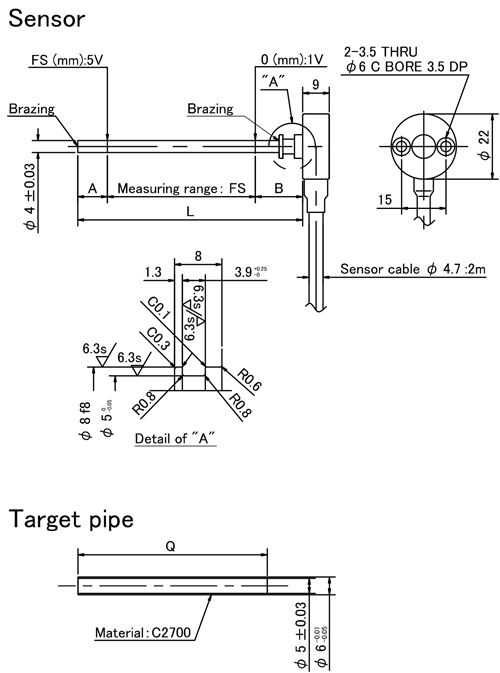

LFH flange type (Cable pull-out direction : Horizontal)

R8H screw type (LP40-100-R8H)

Application examples

Amplifier

Specification

| Model | CV06A | CV06D | CV05 | CVS5 CVS5(Resin case type) |

|---|---|---|---|---|

| Power-supply voltage | DC12~24V ±10% | DC18~24V ±10% | DC12~24V ±10% | DC9~16V ±10% |

| Current consumption | 50mA or less | 100mA or less | 40mA or less | |

| Output voltage | Analog output DC1~5V | |||

| Resolution | Approx 1/2000 of measuring range | |||

| Responsiveness | About 4kHz(-3dB) | |||

| Operating temperature range | -20~80℃ (No condensation) | |||

| Temperature characteristics | 0.025%/FS or less (0 to 60℃ @ center of measurement range) | |||

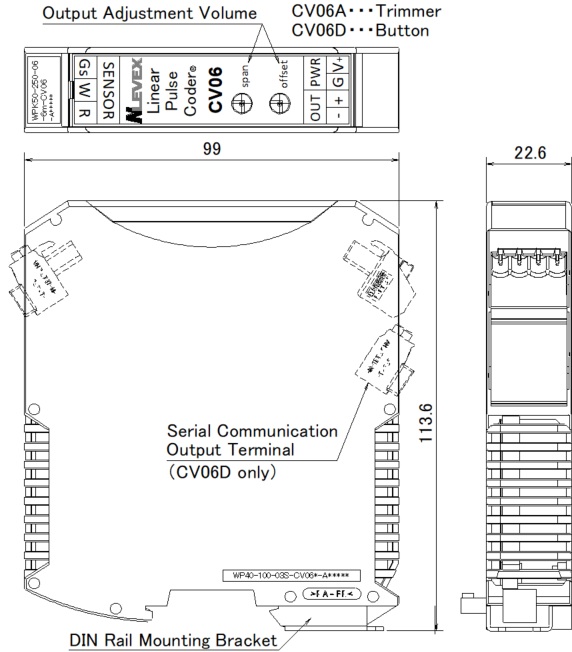

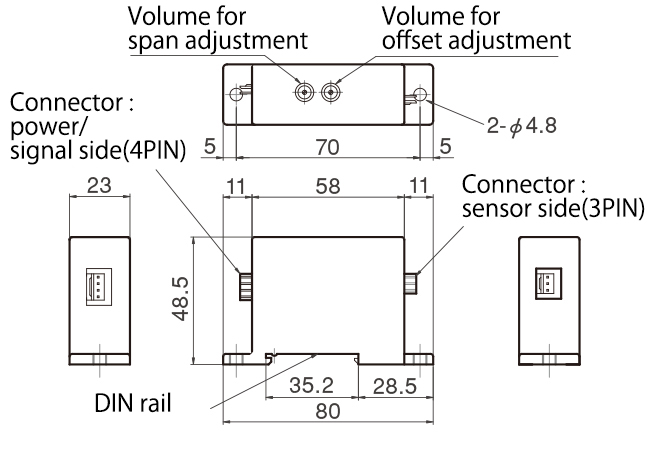

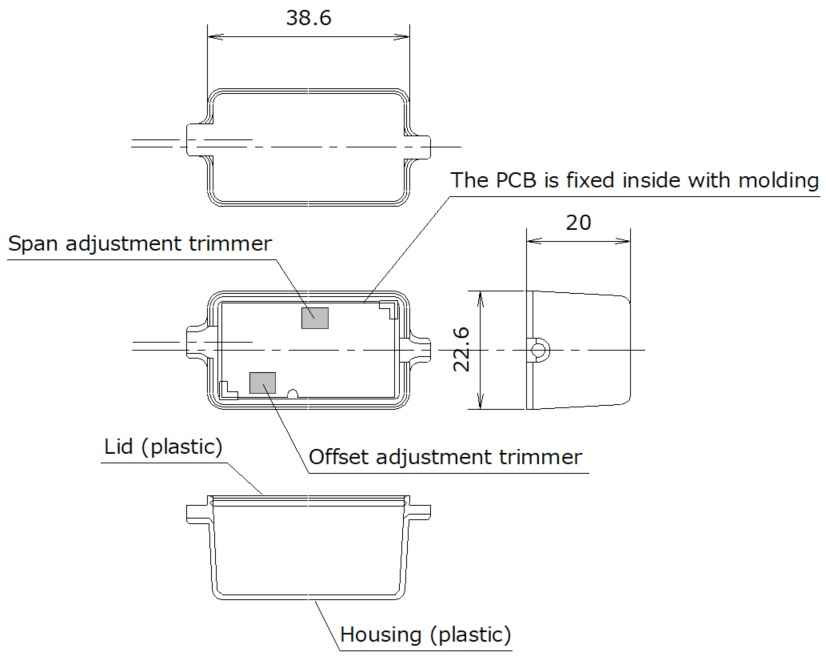

Outline drawing

CV06A/CV06D

CV06新_0N2A9201-Photoroom.png)

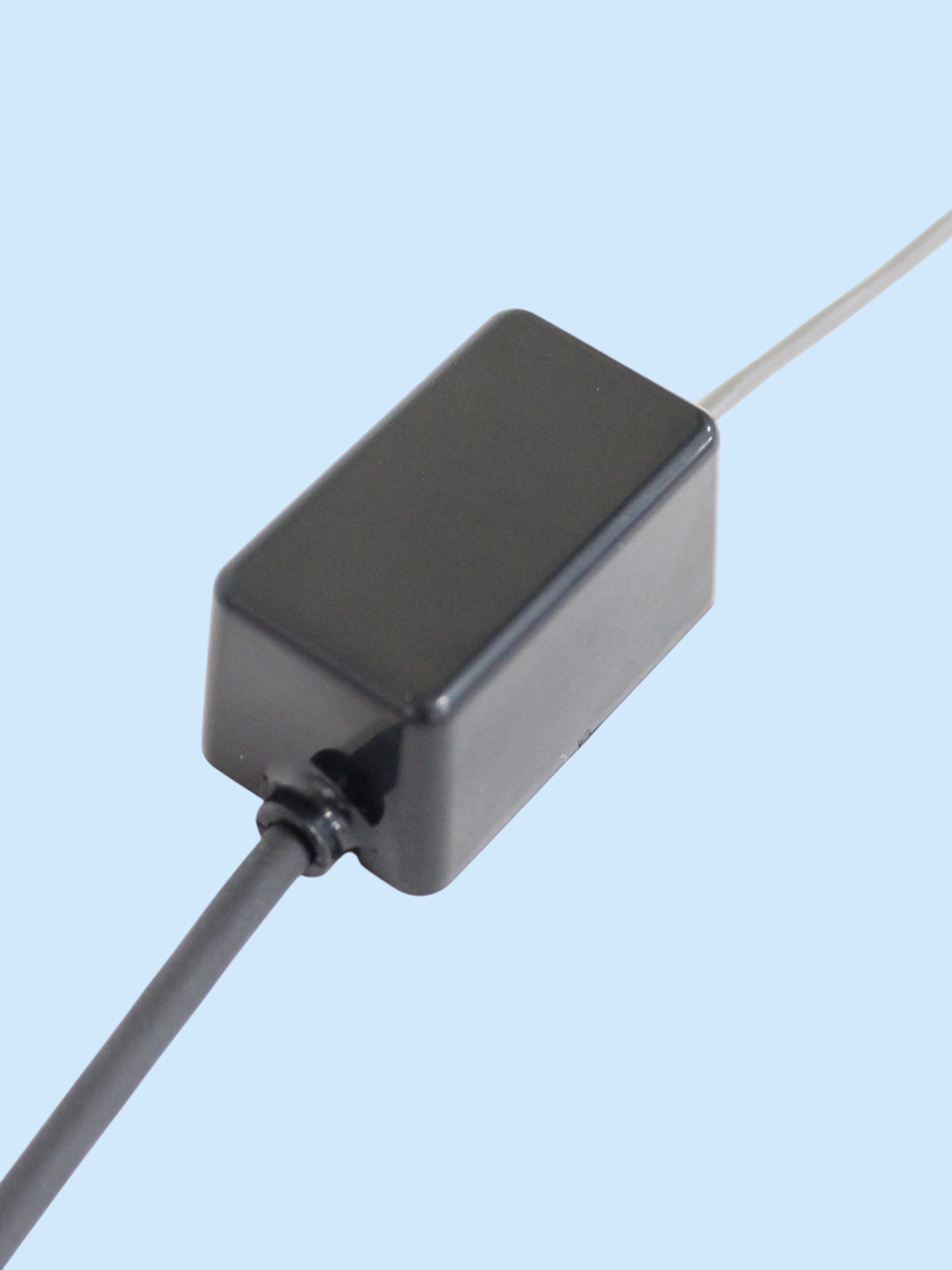

CV05

CV05新_0N2A9211-Photoroom.png)

CVS5

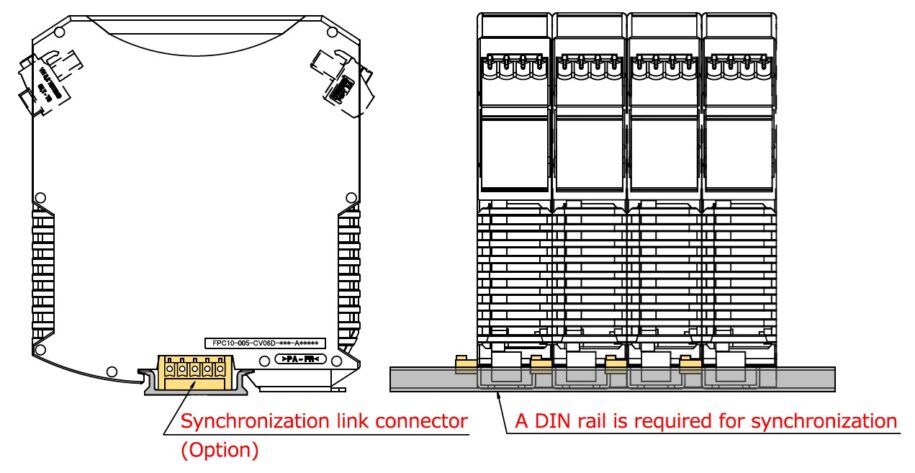

(Options) Synchronous processing

Purpose

When multiple sensors of the same type are used, periodic interference noise may occur in the output.

To counter this, noise is reduced by synchronizing the signal generation circuits in each amplifier.

To counter this, noise is reduced by synchronizing the signal generation circuits in each amplifier.

Synchronizable amplifier

CV06A

CV06D

CV06D

Synchronization method

Using a dedicated synchronization connector (on DIN rail)

Precautions for use

– Only connect sensors and amplifiers with the same serial numbers.

– The master amplifier is fixed.

– Slave amplifiers do not operate in isolation.

– Operation with a reduced number of slave amps connected is possible if they are the same model.

– Each amplifier requires a power supply.

– The master amplifier is fixed.

– Slave amplifiers do not operate in isolation.

– Operation with a reduced number of slave amps connected is possible if they are the same model.

– Each amplifier requires a power supply.

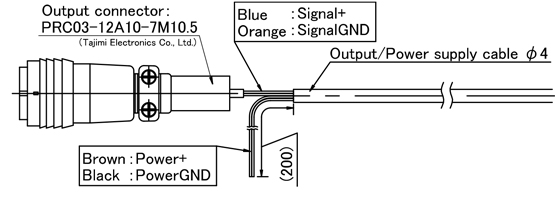

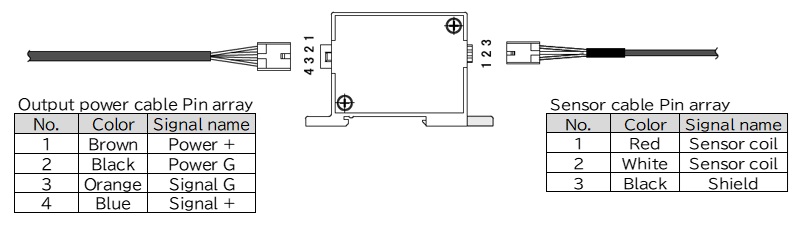

Output – power cable

Connection configuration

CV06A/CV06D

_NLVX_250218.jpg)

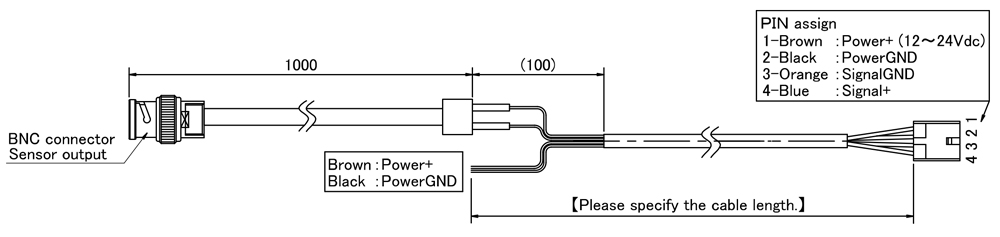

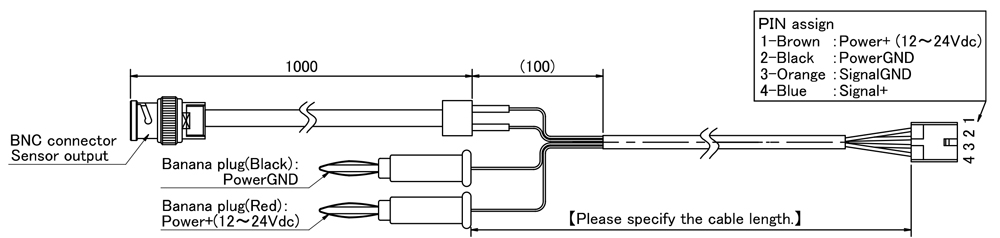

CV05

(End treatment example) * We fit a range of connectors.

(Signal side) With BNC conversion cable

(Signal side) BNC conversion cable + (Power supply side) Banana plug

(Signal line) With Tajimi Electronics connector